Bearings are surprisingly delicate components despite their widespread use in heavy machinery. They require bearing maintenance, careful handling, and storage to ensure they continue functioning as intended for an extended period of time. Here are some maintenance tips to ensure your bearings can bear the load efficiently.

Practice proper handling

As complex and precise components, bearings necessitate careful handling and storage to avoid contamination, which can reduce their effectiveness or cause failure. Proper storage, preventing exposure to airborne contaminants, and refraining from direct force application are all critical practices. Before mounting, thoroughly inspect the housing and shaft to ensure they are in good physical condition for bearing operation. A crucial step in bearing maintenance is to remove any nicks or burrs and wipe surfaces clean with a soft cloth. When mounting, it’s critical to use the proper method, which varies depending on whether the bearing has a cylindrical or tapered bore. It is critical to emphasize the importance of applying pressure only with a press fit to avoid damage to raceways.

Strategic heat management

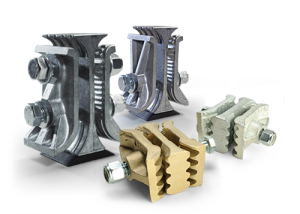

Overheating can cause permanent deformation or softening of bearing steel, lowering load-carrying capacity and resulting in failure. Induction heaters are recommended for the shrink-fit method to reduce this risk, as they eliminate the need for direct flame application. Furthermore, using the proper tools is critical for delicate bearing handling. When it comes to bearing maintenance, bearing pullers, fitting toolkits, oil injectors, hydraulic nuts, and induction heaters are all designed to reduce the risk of damage during various stages, such as mounting or dismounting, ensuring optimal performance and bearing longevity.

Proper lubrication

Bearing maintenance is essential for preventing corrosion and ensuring optimal bearing performance. As preventive measures, wear gloves when handling and applying water-resistant grease in moist environments. Consider using bearings made of alternative materials in extremely corrosive environments. Prioritize proper lubrication as a critical component in preventing failure. Follow the manufacturer’s recommendations for lubricant grade, type, application method, and quantity. Consider environmental conditions, temperature, operation speed, and load for a holistic approach to improving performance and extending lifespan.

These are just some tips on how to take care of your bearings. For more information, visit us today.