Deciding which conveyor belt fasteners to use can be confusing, but an essential step in splicing a belt. They join the ends of conveyor belts together, thus creating a continuous loop that would allow the belt to move smoothly along the conveyor structure. Choosing the wrong one can lead to premature wear and cause a malfunction in the belt splice.

Here are the factors to be considered when selecting the appropriate conveyor fastener.

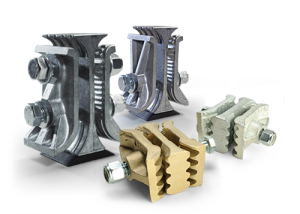

Fastener Type

There are different belt fastener types available in the market, such as mechanical fasteners, plate fasteners, hinged fasteners, and others. Each type has its advantages and is suitable for specific belt materials and applications. For instance, mechanical fasteners are versatile and offer a strong grip, while hinged fasteners allow for easy installation and maintenance. Another deciding factor on which belt fasteners to use would be tied to the pulley diameter. Hinged fasteners are commonly used for smaller pulley diameters as they can bend around a tighter turn in the system. On the other hand, solid plate styles are used for their longer life and to prevent sifting, provided that either style is appropriate for your belt and pulleys.

Strength and Load Capacity

Determine the conveyor system’s load capacity and tension requirements. The fasteners that should be used would be able to withstand the application’s tension and stress without compromising the belt’s integrity. The materials these fasteners would be made out of depend greatly on whether it is used for light or heavy duty. Some examples of light-duty belt fasteners would be common bar lacing, stapled plate fasteners, and plastic hinged plate fasteners, while bolted and riveted plate fasteners and stapled, riveted and bolted hinged fasteners are used for heavy duty.

Before finalizing your decision, it’s a good idea to consult with conveyor system experts or suppliers who can help you assess your specific needs and recommend the most suitable fastener options. Visit us today at KC Supply Co. for any further questions.